We are proud to announce that Josef Füssl won a FWF START grant with the submitted project “Making wood predictable through computational methods“. Congratulation!

Project leader: Josef Füssl

Duration: 6 years

Agency: FWF START-Programm

Abstract:

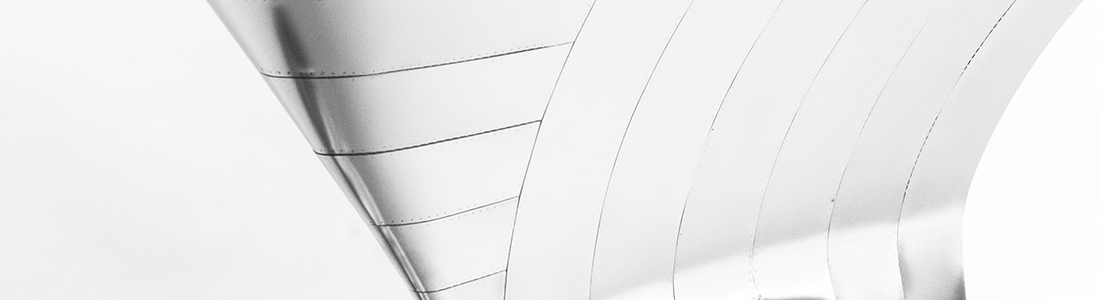

Wood as structural bearing material is often encountered with skepticism and, therefore, it is not used as extensively as its very good material properties would suggest. Beside building physics and construction reasons, the main cause of this skepticism is its quite complex material behavior, which is the reason that design concepts for wood have so far not achieved the prediction accuracy of those from other building materials.

Wood, as a naturally-grown material, exhibits a highly inhomogeneous material structure, characterized by randomly occurring knots. Thus, for the prediction of effective mechanical properties, advanced computational tools are required, which are able to predict as well as consider multidimensional strength information at different scales of observation. 3D virtual models of wooden boards, revealing strength-influencing morphological characteristics (like knots and fiber deviations) would represent the necessary basis for such tools but are not available until now. For this reason, existing stochastic approaches, required to account for material property fluctuations in wood, are forced to solely rely on experimentally-obtained data, heavily limiting their capabilities.

Thus, the proposed project aims at establishing mechanically-sound and experimentally-validated links from the microstructure of wood up to the product scale through the development and application of computational, mainly finite-element based, tools. Special focus will be laid on the description of cracking mechanisms around knots and on direct numerical approaches for efficient access to the mechanical behavior of knot groups. The breakthrough of the project will come from the combination of these tools with new algorithms for morphology identification of wooden boards and modern stochastic approaches, including genetic optimization algorithms with ideas borrowed from evolutionary theory – and, overall, from their assembly into uniform frameworks, so-called virtual wood labs. These labs will be able to virtually assemble any kind of wood-based product based on realistic information of the raw material and, furthermore, reliably predict its mechanical behavior under arbitrary loading situations and boundary conditions. This in turn allows the implemented stochastic approach to add probabilistic information to effective properties and to identify, through sensitivity analysis, key parameters influencing them. Finally, genetic optimization algorithms will re-assembly wooden boards within the considered wood-based products until the raw material is optimally utilized.

Finally, wood would be predictable through computational methods for the first time, and these virtual wood labs are expected to pave the way to smart algorithmic-driven manufacturing processes following the vision of Industry 4.0, targeted computer-based development of new wooden structural elements, and integration of wood analysis into general concepts of computational design. This will prepare timber industry for the future challenge of our society to efficiently design, produce, and build sustainable infrastructure with all the possibilities provided by the fast-developing areas of digitalization and cognitive computing.